We Train Pilots in Simulators Before They Fly. Why Do We Still Train Rig Workers on PowerPoint?

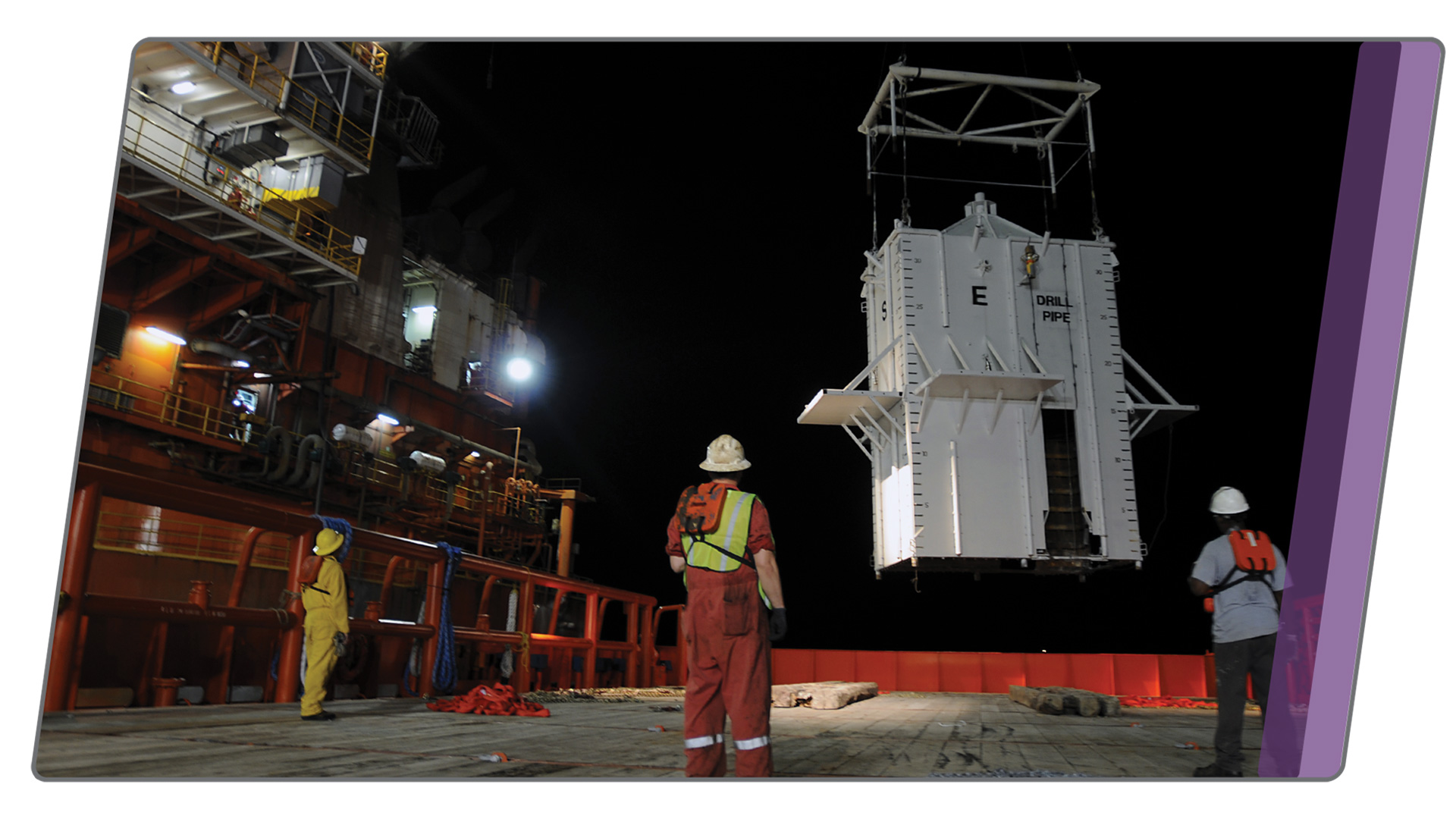

The offshore drilling industry operates some of the most complex, dangerous machinery on Earth. We drill through miles of rock beneath miles of ocean, managing pressures that could cut steel like butter and temperatures that fluctuate from arctic cold to furnace heat. We ask workers to make split-second decisions where a wrong call doesn’t just mean downtime—it means potential catastrophe.

Yet we train these same workers with classroom lectures, static diagrams, and maybe—if they’re lucky—a few hours on a mock-up that bears as much resemblance to a real emergency as a fire drill does to an actual inferno.

The numbers tell a story we can’t ignore anymore. The human factors that killed 11 workers on the Deepwater Horizon remain fundamentally unchanged. We’ve upgraded the hardware, tightened the regulations, but the wetware—the human element—still operates on training methodologies from a previous century.

The Brutal Reality of Offshore Work

Let’s start with what the O*NET occupational profiles reveal about the daily reality of offshore drilling positions. These aren’t statistics pulled from academic studies or industry PR materials. They’re the federal government’s systematic analysis of what these jobs actually demand.

Rotary Drill Operators—the senior technical positions on the drill floor—face 100% exposure to outdoor weather conditions every single shift. Not occasionally. Not frequently. Every single shift, regardless of whether that’s a Gulf hurricane or North Sea winter storm. They operate in environments where 97-100% of the time requires full protective equipment, where 86-97% of the workday involves exposure to hazardous equipment and volatile contaminants.

But here’s the number that should stop every executive cold: these positions require a 75/100 importance rating for “Problem Sensitivity”—the ability to detect when something’s wrong before it becomes catastrophic. Three-quarters of their value comes from pattern recognition in chaos. From sensing the abnormal vibration, the unexpected pressure reading, the flow rate that doesn’t quite match what it should.

Now consider that these same positions rate 88/100 for “Training Others” as a core competency. We’re asking people who work in sensory overload conditions to simultaneously serve as instructors, mentors, and safety leaders for their crews. Derrick Operators, working 85-90 feet above the rig floor on a platform called the “monkeyboard,” must lean out wearing safety harnesses to guide pipe stands while knowing the location of the “Geronimo line”—their emergency escape cable if everything goes wrong.

Service Unit Operators maintain equipment with a mean time to failure of 97 days. Let that sink in. On average, critical safety equipment fails every three months. The main control systems account for 45% of all failures. These aren’t rare edge cases—they’re routine realities that workers must be prepared to handle.

Roustabouts, the entry-level positions earning $47,510 annually, still face the same 100% extreme exposure. They’re expected to respond to emergency situations despite requiring “little to no prior experience” for the role. We throw them into one of Earth’s most unforgiving environments and hope that PowerPoint slides and safety videos have adequately prepared them for the moment when normal operations transform into crisis.

Deepwater Horizon: A Masterclass in Systematic Failure

The Deepwater Horizon disaster provides the most comprehensively documented case study of how human factors combine with technical failures to create catastrophe. Every investigation—the National Commission, the Chemical Safety Board, the Coast Guard, the Bureau of Ocean Energy Management—reached the same conclusion: the disaster was entirely preventable.

But “preventable” doesn’t mean “simple.” The disaster required every single safety barrier to fail in sequence. The cement job failed because BP used 6 centralizers instead of 21. The cement bond log that would have detected this failure was cancelled to save $128,000 and 9-12 hours. The negative pressure test showed clear signs of failure—pressure building back to 1,400 psi when it should have remained at zero, 15 barrels of fluid returned instead of the expected 5.

Yet experienced crews explained away these readings as a “bladder effect”—a phenomenon that post-incident investigations found no evidence actually exists. Think about that. Highly trained professionals, under pressure to complete a well that was 43 days behind schedule and $58 million over budget, collectively convinced themselves that impossible readings were acceptable because of a fictional phenomenon.

The human factors analysis reveals even deeper problems. A confidential survey conducted weeks before the disaster found that 46% of workers feared reprisals for raising safety concerns. Nearly half the workforce was self-censoring in an environment where speaking up could prevent disaster. The safety manual was described as “unstructured” and “hard to navigate.” Multiple workers expressed concerns that drilling priorities were taking precedence over maintenance and safety.

When the crisis began, crews had approximately 40 minutes between the first indicators and the explosion. Forty minutes where proper training could have made the difference. But confusion reigned. The Offshore Installation Manager was in the shower. The chain of command fragmented. Nobody took ownership of reconciling contradictory pressure readings. The crew diverted gas to the mud-gas separator instead of overboard, venting explosive vapors directly onto the rig.

The blowout preventer—the final safety barrier—failed due to a phenomenon called “effective compression” that the industry didn’t even know existed. When crews activated the emergency systems, pressure differentials caused the drill pipe to buckle, shifting it outside the reach of the blind shear ram. The Chemical Safety Board warned this hazard “could impact even best offshore companies with high equipment maintenance standards” and “could compromise proper functioning of other blowout preventers still deployed around the world.”

The Statistical Reality of “Never Again”

Since Deepwater Horizon, the industry has made significant improvements. The International Association of Drilling Contractors data show a 50% reduction in Lost Time Incident rates from 0.26 in 2013 to 0.13 per 200,000 hours in 2024. Fatalities decreased 64% from 22 to 8 annually. These aren’t small achievements.

But let’s examine what experts say about the probability of recurrence. The SINTEF Offshore Blowout Database documents 573 blowouts worldwide since 1955. High-pressure/high-temperature wells—increasingly common as we push into frontier regions—show blowout frequency of 1.9×10⁻³ per drilled well, one order of magnitude higher than “normal” deepwater wells. The historical data suggest major spill recurrence rates “in the order of decades rather than centuries.”

The National Commission members stated bluntly in 2020: “Of course it could happen again.” They concluded that “another such spill is largely inevitable—despite a decade’s worth of attempts to prevent just that.” The 2023 National Academies assessment found that while improvements have been made, “an industry-wide emphasis on strengthening a culture that supports safety and guidance for all operators and contractors is not apparent.”

Most damning, the report noted that “offshore process safety practice has lagged behind other high-hazard industries and has lagged behind offshore technology development.” We’ve gotten better at drilling deeper, but not necessarily safer. The operator-contractor interface that failed at Macondo—with 80% of offshore work performed by contractors not directly subject to Safety and Environmental Management Systems requirements—remains a systemic vulnerability.

Why Traditional Training Fails in Complex Systems

Traditional training methods—classroom instruction, procedural memorization, tabletop exercises—fail to address the cognitive and emotional realities of crisis situations. When alarms are screaming, gas is venting, and you have seconds to make decisions, the calm recollection of classroom lessons evaporates.

Research on high-reliability organizations shows that expertise in complex systems requires pattern recognition developed through repeated exposure to varied scenarios. But you can’t repeatedly expose workers to actual well kicks, BOP failures, or gas influxes. The first real emergency they face might be their last.

The Deepwater Horizon crews had all required certifications. They conducted regular drills. BP executives were on the rig that very morning celebrating seven years without a lost-time incident. Yet when faced with ambiguous, contradictory signals under time pressure, their training proved inadequate.

The investigation found that fire drills had become routine, always conducted at the same time on the same day. Crew members admitted being hesitant to don protective equipment during drills because it was uncomfortable. The Offshore Installation Manager had to remind crews to treat drills as “the real deal.” This normalization of training as performance rather than preparation created a false sense of readiness.

The VR Revolution: From Simulation to Preparation

Virtual reality training addresses every failure point identified in the Deepwater Horizon disaster and the broader challenges revealed by occupational analysis. We don’t mean eliminating traditional classroom training, but instead adding a critical layer of experiential learning that’s impossible to achieve any other way.

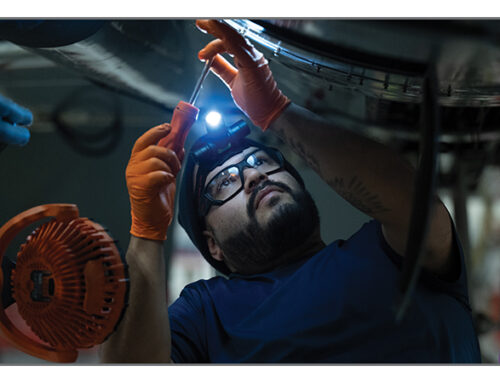

Imagine a Rotary Drill Operator experiencing a kick at 2 AM on their 19th day of rotation. In VR, we can replicate the fatigue, the sensory overload, the contradictory instrument readings. We can introduce the “bladder effect” scenario and let them discover for themselves why it’s physically impossible. They can make the wrong decision, experience the consequences, and try again—building the pattern recognition and decision-making capabilities that no amount of classroom instruction can provide.

For Derrick Operators, VR can simulate working at height in severe weather, handling equipment failures while maintaining balance on the monkeyboard, making emergency evacuation decisions. They can practice using the Geronimo line in conditions where real-world training would be impossibly dangerous.

Service Unit Operators can experience the full range of equipment failures documented in reliability studies. Not just learning about the 156 BOP failures per 15,056 days of service, but experiencing them—the spurious opening of connectors, the ram leakage, the total loss of control. They can develop the troubleshooting instincts and emergency response patterns that transform theoretical knowledge into practical capability.

Even Roustabouts, with minimal prior experience, can enter VR environments that build situational awareness and hazard recognition from day one. Instead of learning about gas detection through videos, they can practice identifying leaks in a 360-degree environment with realistic audio and visual cues.

Addressing the Human Factors

But VR’s greatest potential lies in addressing the human factors that contributed to Deepwater Horizon. The 46% of workers who feared reprisals for raising safety concerns can practice assertive communication in virtual scenarios without real-world consequences. They can experience situations where speaking up prevents disaster, building the confidence to overcome hierarchical pressure.

Teams can practice the critical negative pressure test scenario with different variations—sometimes the readings are genuinely acceptable, sometimes they indicate severe problems. This variability prevents the proceduralization that plagued traditional drills and builds genuine diagnostic capability.

Leadership scenarios can place experienced operators in situations where they must take command during emergencies, make decisions with incomplete information, and manage teams under extreme stress. The confusion about authority that paralyzed Deepwater Horizon’s response can be systematically addressed through repeated practice in varied scenarios.

Most critically, VR can simulate cascading failures—situations where multiple systems fail simultaneously, where standard procedures break down, where creativity and adaptation become essential. These are the scenarios that classroom training can describe but never truly prepare workers to handle.

The Economics of Prevention

The Deepwater Horizon disaster cost BP over $65 billion in cleanup, fines, and settlements. The rig itself, valued at $560 million, was a total loss. The human cost—11 lives—is incalculable. Against these numbers, the investment in comprehensive VR training systems becomes not just reasonable but obligatory.

Modern VR training platforms can be deployed across entire fleets, updated with lessons learned from near-misses and incidents, and customized for specific rigs and operations. The same scenario can be run hundreds of times with variations, building the deep pattern recognition that distinguishes expert operators from competent ones.

The technology now exists to create photorealistic rig environments, accurate physics simulations, and biometric monitoring that tracks stress responses and decision-making patterns. We can quantify training effectiveness in ways impossible with traditional methods, identifying workers who need additional support before they face real emergencies.

Why Immersion is Imperative

We ask offshore workers to manage forces that dwarf human comprehension—pressures that could instantly crush submarines, temperatures that fluctuate across hundreds of degrees, volatile compounds that can transform from resource to explosive in seconds. We place them in environments where the nearest help might be hundreds of miles away, where evacuation in severe weather might be impossible, where a single wrong decision could kill everyone on board.

These workers deserve training systems that match the complexity and danger of their environment. Not PowerPoints that describe emergency procedures, but immersive experiences that build the automatic responses and pattern recognition that save lives when conscious thought is too slow.

The technology exists. The need is documented in exhaustive detail. The cost of inaction is measured in billions of dollars and human lives. The only question remaining is how many more disasters we need before the industry universally adopts training methods that match the risks our workers face every single day.

Virtual reality training for offshore drilling isn’t a luxury or a technological novelty. It’s an imperative driven by hard data and written in the blood of those who died because their training couldn’t prepare them for the moment when everything went wrong. We have the ability to ensure that every worker has failed safely a hundred times before they face their first real emergency.

The numbers don’t lie. The technology is proven. The only variable is whether we have the courage to admit that traditional training alone isn’t enough and the wisdom to act before the next preventable disaster reminds us why preparation matters more than hope.

Because on an offshore rig, hope isn’t a tactic. And neither is PowerPoint.