Diagnostic Technicians: Talent Assessment and Simulation Challenges for Hiring

Diagnostic Technicians: Talent Assessment and Simulation Challenges for Hiring

Picture this:

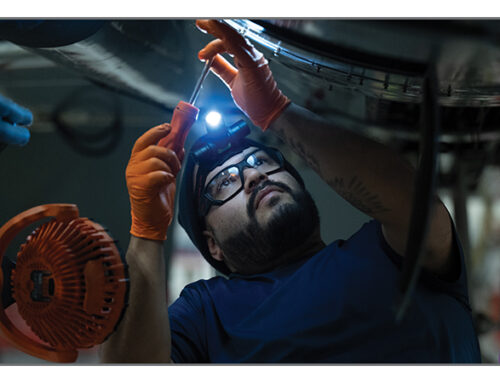

A technician stands in front of a rack of servers, oscilloscope in one hand, soldering iron cooling on the bench nearby. They’ve been on their feet for 10 hours of a 12-hour shift. The server fans roar at 85 decibels. One wrong move with that probe on a 600-volt power supply, and they’re headed to the emergency room.

This is the reality of today’s Diagnostic Technician – a role that’s evolved far beyond what most hiring managers imagine. It’s a position where a moment’s inattention can mean the difference between a successful repair and a catastrophic injury. Where the mental demands rival those of air traffic controllers, but the physical requirements match those of warehouse workers.

More Than Meets the Eye

When you post a Diagnostic Technician position, you might think you’re looking for someone who can troubleshoot computers and run some tests. The reality? You’re searching for a rare combination of electronics engineer, software programmer, athlete, and detective.

Beyond Linux and server troubleshooting, these professionals navigate a minefield of hazards daily. They work with high-voltage systems that can deliver fatal shocks. They perform microsurgery on circuit boards with components smaller than a grain of rice. They lift 50-pound servers repeatedly while maintaining the focus of a bomb disposal expert.

Consider what happens in a typical hour of their workday. A Diagnostic Technician might start by debugging a server that won’t boot, requiring them to trace signals through a dozen circuit boards using equipment that costs more than most cars. Next, they’re crawling under a rack to trace network cables, all while avoiding the spinning fans that could catch loose clothing. Then they’re back at their bench, using a microscope and steady hands to replace a chip the size of a f ingernail, knowing that one slip could destroy a $5,000 board.

The numbers tell a sobering story. Manufacturing faces the worst hiring odds across all industries – with some organizations screening 200 applicants to make just one hire. Only 3% of applicants even get an interview. In electronics manufacturing specifically, companies report achieving only 36% of their hiring goals, the lowest performance across all sectors surveyed in 2024.

Why such dismal statistics? Because the role demands an almost impossible blend of skills that traditional education rarely provides together. It requires someone who can think like an engineer, work like a craftsperson, and maintain the vigilance of a safety inspector – all while racing against production deadlines.

The Physical Reality No One Talks About

Forget the image of technicians sitting comfortably at benches. Today’s Diagnostic Technicians are industrial athletes. They often need to stand for entire 12-hour shifts. They work in server rooms where temperatures soar and noise levels require double hearing protection. They bend, reach, and twist to access equipment in cramped spaces.

The physical demands read like a fitness test:

• Standing and walking for up to 12 continuous hours

• Lifting servers weighing 30-50 pounds multiple times per shift

• Fine motor control for handling components smaller than rice grains

• Working in hot aisles where temperatures exceed 95°F

• Maintaining concentration despite 85+ decibel ambient noise • Bending and crouching to access equipment at all rack levels

• Bending and crouching to access equipment at all rack levels

But physical endurance is only part of the story. The sensory demands are equally intense. Technicians must maintain visual acuity to spot hairline cracks on circuit boards. They need steady hands that don’t shake even after 10 hours of work. They must hear subtle changes in fan noise that indicate impending failure, all while wearing hearing protection.

The injury risks read like a medical textbook. Arc flash burns from power supplies. Injured fingers from server fans that spin up unexpectedly. Back injuries from repetitive lifting. Respiratory issues from solder fumes. Heat exhaustion from working in poorly ventilated server rooms. Even experienced technicians face these dangers when fatigue sets in during hour 11 of their shift.

When Things Go Wrong: Real Incidents from the Floor

The true danger of this role becomes clear when examining actual incidents from the manufacturing floor. These aren’t statistics – they’re real events that happened to real technicians, often with life-altering consequences.

1. The Remote Activation Nightmare:

A senior technician was replacing memory modules inside a server chassis when a colleague in another building remotely powered on the system through the Baseboard Management Controller. The technician’s hand was instantly caught in the high-speed cooling fans, resulting in deep lacerations requiring 30 stitches and two months of recovery.

2. The Arc Flash Incident:

During routine power supply testing, a technician’s probe slipped while measuring a 600V rail. The resulting arc flash caused second-degree burns to his face and hands, melted his safety glasses to his skin, and required three months of painful treatment. The technician now has permanent scarring and reduced dexterity in his dominant hand.

3. The Cascade Failure:

While running stress tests on a rack of 20 servers, one unit’s power supply failed catastrophically, sending a surge through the shared power distribution unit. The explosion of capacitors sent shrapnel across the test area, injuring two technicians with flying debris and causing permanent hearing damage to one who wasn’t wearing protection.

4. The Invisible Killer:

A technician working alone on a night shift was exposed to excessive lead fumes from eight hours of continuous desoldering work. The ventilation system had been turned off to reduce noise. She developed severe respiratory distress and was found unconscious at her bench. Blood tests revealed dangerous lead levels that required months of chelation therapy.

5. The Fatigue Factor:

At hour 11 of a 12-hour shift, an exhausted technician connected a 12V supply to a 3.3V test point. The resulting component explosion sent ceramic fragments into his eyes, causing corneal abrasions despite safety glasses. Investigation revealed this was his sixth consecutive 12-hour shift.

6. The Software-Triggered Injury:

A technician using remote access software accidentally executed a script that caused multiple servers to power cycle simultaneously. Another technician working on the rack was struck by a sliding server chassis that hadn’t been properly secured, suffering a concussion and compressed vertebrae.

These incidents share common themes: the intersection of multiple hazards, the role of human factors like fatigue and communication failures, and the severe consequences of momentary lapses in attention. They underscore why finding technicians with the right mix of technical skills and safety awareness is literally a matter of life and death.

The Skills Gap That’s Breaking the Industry

Here’s what makes hiring nearly impossible: Modern diagnostic work requires both old-school electronics knowledge and cutting-edge software skills. Technicians must read electrical schematics like a native language while also writing Linux scripts and navigating BMC interfaces. They need the steady hands of a surgeon for soldering and the problem-solving skills of a software engineer for system debugging.

Traditional education fails this need spectacularly. Universities teach either hardware or software, rarely both. Technical schools focus on theory without the hands-on troubleshooting experience. Community colleges might cover basic electronics but lack access to modern server hardware. The result? Fewer than 4,000 qualified graduates annually for an industry needing tens of thousands.

The CHIPS Act promises to create 160,000+ engineering and technician jobs, but industry

analysts project a 90,000 technician shortage over the next decade. This isn’t just a numbers

problem – it’s a fundamental mismatch between what schools teach and what the job requires.

Consider the actual knowledge domains a Diagnostic Technician must master:

• Electronic Theory: Understanding circuits, signals, and power systems

• Computer Architecture: How CPUs, memory, and peripherals interact

• Operating Systems: Particularly Linux command line and system administration

• Networking: TCP/IP, routing, and troubleshooting connectivity

• Programming: At least basic scripting for automation

• Mechanical Skills: Handling tools, assembly, and repair techniques

• Safety Protocols: Lockout/tagout, ESD procedures, hazardous materials

The most successful technicians often come from unexpected backgrounds – military

electronics technicians, passionate computer builders, even auto mechanics who taught

themselves programming. They share one trait: the ability to think across disciplines.

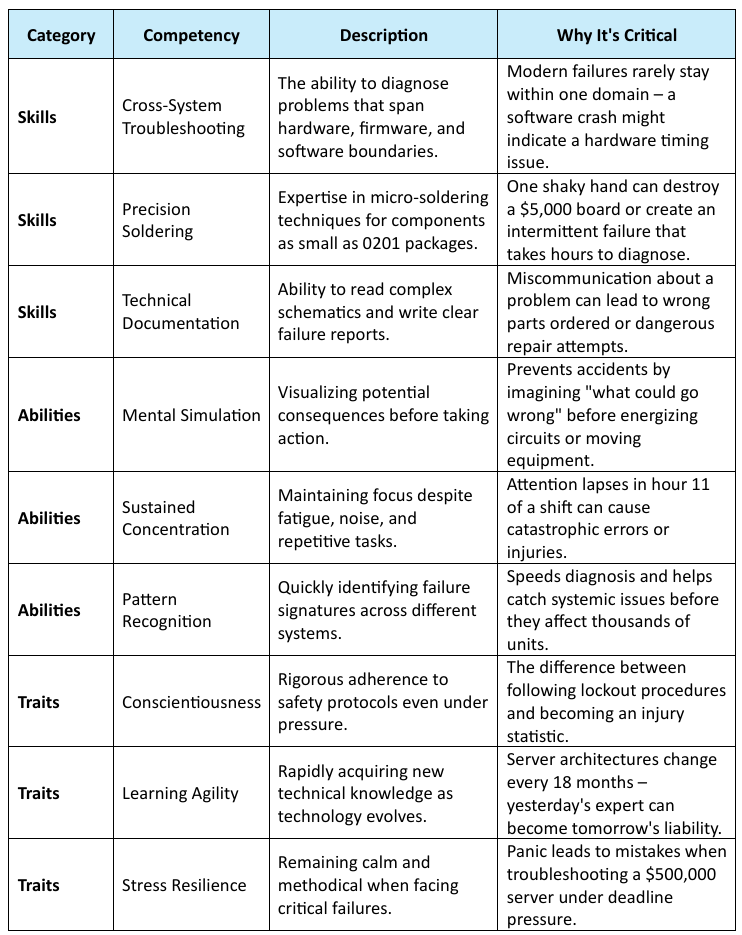

What Actually Predicts Success

After analyzing thousands of safety incidents and performance records, clear patterns emerge about who succeeds in this role. It’s not just technical knowledge. The best Diagnostic Technicians possess what researchers call “mental simulation” – the ability to visualize what could go wrong before it happens.

This mental simulation manifests in various ways:

• Pausing before connecting power to think through all possible outcomes

• Noticing subtle anomalies that others miss – a slight discoloration, an unusual smell, a different sound

• Automatically checking for energized circuits even when told equipment is powered down

• Visualizing current flow through circuits to predict failure points Consider these real scenarios that separate great technicians from injured ones:

Scenario 1:

A technician needs to test a repaired power supply. The average tech connects it and powers on. The exceptional tech first checks all capacitors for proper discharge, verifies correct voltage settings, ensures proper grounding, positions themselves away from potential arc points, and has a fire extinguisher within reach.

Scenario 2:

Production pressure mounts to quickly diagnose a server failure. The average tech skips lockout procedures to save time. The exceptional tech takes the extra 30 seconds, knowing that their family expects them home intact.

Scenario 3:

A new type of server arrives with unfamiliar architecture. The average tech dives in using assumptions from previous models. The exceptional tech stops, obtains proper documentation, and identifies the differences before touching anything.

These mental habits matter more than years of experience. New technicians with strong hazard recognition often outperform veterans who’ve grown complacent. In fact, injury data shows a dangerous spike at the 3-5 year mark when confidence exceeds caution.

Finding Your Needle in the Haystack

So how do you identify these rare individuals among hundreds of applicants? Stop looking for perfect resumes. Instead, look for evidence of success predictors:

Cross-Discipline Thinking: Candidates who built their own computers AND wrote code. Who worked on cars AND learned networking. The ability to bridge physical and digital worlds is crucial. Ask about projects that required both hands-on work and analytical thinking.

Physical Awareness: Ask about their experience with demanding physical work. Can they handle 12-hour shifts? Do they understand workplace safety? Previous warehouse, military, or construction experience often translates well. But also look for subtler indicators – do they mention ergonomics when describing their workspace? Do they talk about taking breaks to maintain focus?

Problem-Solving Stories: Don’t ask about their education. Ask them to describe the hardest technical problem they’ve solved. Look for systematic thinking, persistence, and creativity. Better yet, ask about a time they prevented a problem before it occurred. The best technicians are proud of the disasters that didn’t happen.

Risk Recognition: Present scenarios from real incidents. “You’re testing a server and need to check internal components. What’s your first step?” The best candidates immediately mention powering down and lockout procedures. They might even ask about the location of the emergency power cutoff.

Learning Indicators: The technology changes too fast for static knowledge. Look for evidence of continuous learning – personal projects, online courses, curiosity about new technologies. Ask what they’ve taught themselves recently.

Stress Response: How do they handle pressure? Ask about tight deadlines or difficult customers. Look for methodical approaches rather than heroic scrambling. The technician who stays calm prevents accidents.

Consider using practical assessments that go beyond traditional interviews:

• Have them trace a circuit on a schematic and explain potential failure points

• Present a damaged board and ask them to describe their diagnostic approach

• Give them a multimeter and basic components to demonstrate safe testing procedures

• Use simulation-based assessments that measure hazard recognition and decision

making

The Path Forward

The demand for Diagnostic Technicians will only intensify as AI infrastructure expands and manufacturing returns to domestic facilities. Major semiconductor investments are creating thousands of positions, while the current workforce ages out. By 2030, analysts project 1.9 million unfilled manufacturing positions, with technical roles facing the most severe shortages.

Forward-thinking companies are abandoning traditional requirements and pioneering new approaches:

Innovative Partnerships: Leading manufacturers partner with community colleges to create custom training programs. These aren’t traditional courses – they’re intensive bootcamps using actual production equipment, teaching both technical skills and safety culture.

Apprenticeship Renaissance: Companies are reviving apprenticeship models, pairing new hires with senior technicians for 6-12 months. This addresses both skills transfer and the critical safety mindset that can’t be taught in classrooms.

Technology-Enhanced Assessment: Simulation-based assessments now measure the exact competencies needed – from hazard recognition to systematic troubleshooting. When a role requires visualizing invisible dangers, why rely on resumes and interviews?

Career Pathway Development: Smart companies create clear progression from entry-level to senior technician to engineering roles. This attracts ambitious candidates who see long-term opportunity, not just a job.

Safety-First Culture: The best employers prioritize safety over production metrics. They reward technicians who stop unsafe work, even if it impacts deadlines. This culture attracts professionals who value going home intact.

The Diagnostic Technician role represents a critical bottleneck in our technology infrastructure. These professionals ensure the servers powering our digital world actually work. They’re the last line of defense between a manufacturing defect and a data center failure that could impact millions.

Finding them requires rethinking everything we thought we knew about technical hiring. It means looking beyond degrees to find people who can think with both their hands and their heads. It means valuing safety awareness as much as technical skills. Most importantly, it means recognizing that we’re not just hiring technicians – we’re hiring the guardians of our digital infrastructure.

The question isn’t whether you can find the perfect candidate. It’s whether you can recognize the diamond in the rough who has the potential to become one. In a field where mistakes can be measured in third-degree burns or crashed data centers, that recognition might be the most critical skill of all.

The companies that master this challenge won’t just fill positions – they’ll build the technical workforce that powers our digital future. Those that don’t will face more than unfilled positions. They’ll face mounting injuries, quality issues, and the inability to capitalize on the greatest manufacturing expansion in a generation.

The choice is clear. The path forward is challenging. But for those willing to evolve their hiring practices, the reward is nothing less than a competitive advantage in the digital age.