The Hidden Economics of Talent Assessment in Frontline Manufacturing

The Hidden Economics of Talent Assessment in Frontline Manufacturing

A Case Study in Projected Performance-Based ROI

A major U.S. manufacturing organization with over 2,000 frontline workers is confronting a troubling industry trend: across manufacturing, roughly 40% of workplace injuries occur within a worker’s first year. After analyzing their substantial investments in safety training, leadership recognized that the disconnect isn’t in the training itself—it’s in who receives it. As this organization evaluates precision talent assessment for their frontline roles, projected returns on investment extend far beyond traditional cost savings, with potential annual value exceeding seven figures through job performance enhancement alone.

Uncovering Performance Variability

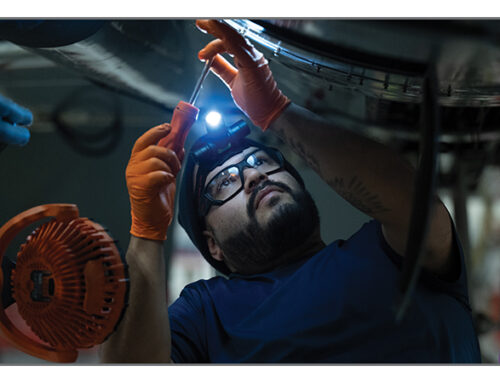

The organization has focused their analysis on frontline maintenance positions—roles that appear straightforward on paper but conceal significant cognitive complexity. Their job analysis reveals that workers must constantly navigate mental tradeoffs: balancing production pressure against safety protocols, predicting cascade effects of equipment adjustments, and recognizing early warning signs of system failures.

This cognitive load drives remarkable variability in worker output. Industry research demonstrates that top performers in cognitively complex roles typically produce at least 40-50% more value than average workers. In maintenance divisions, where a single operator’s error can trigger extended shutdowns costing hundreds of thousands in lost production, this performance gap becomes economically critical.

Taking a specific example: their frontline maintenance positions carry a base compensation of $100,000. Performance modeling suggests average performers would generate roughly equivalent value in productive output. But workers in frontline maintenance positions performing one standard deviation above the mean—those who could be identified through precision assessment—would be expected to produce approximately $140,000-$145,000 in annual value. When projected across 200 annual hires, the potential economic impact could reach $800,000 to $1.2 million annually.

Modeling Three Components of Assessment ROI

The organization’s ROI analysis has identified three interconnected factors that would determine their return on investment:

Performance Variability: Based on industry benchmarks, the difference between top and bottom performers in dangerous manufacturing roles typically exceeds 40%—particularly in positions requiring split-second safety decisions.

Predictive Validity: Well-designed assessment methods that measure cognitive capabilities, safety instincts, and decision-making under pressure can significantly improve selection accuracy over traditional interview-based processes.

Selection Standards: Modeling different thresholds suggests that selecting from the top 25% of assessed candidates could generate returns approaching $1 million per 200 hires, while accepting the top 50% would still potentially realize $800,000-$900,000 in annual value.

These projections represent only the productivity component—before accounting for potential reductions in accidents, decreased supervision requirements, and lower turnover costs.

Quantifying the First-Year Risk Premium

The economic case becomes even more compelling when analyzing industry-wide early-tenure risk data. Analysis of OSHA incident databases covering 780,000+ events reveals that first-year workers account for a disproportionate share of manufacturing accidents and associated costs:

- Direct injury costs averaging $40,000-$75,000 per incident

- Production disruption often exceeding $100,000 per serious event

- Turnover replacement costs running 50-200% of annual salary

- Increased insurance premiums following reportable incidents

Organizations that have implemented cognitive and behavioral assessments predicting safety performance report 30-40% reductions in first-year incidents. For a facility with 200 frontline workers, this could translate to avoiding 3-5 serious incidents annually—potentially preventing $300,000 to $500,000 in direct costs.

Beyond Cost Avoidance: Potential Value Creation

While safety improvements would provide clear cost savings, analysis suggests the primary ROI driver would remain enhanced job performance. Workers who score highly on assessments measuring spatial reasoning, hazard recognition, and systematic decision-making don’t just avoid mistakes—they actively create value through:

- Faster problem diagnosis: Potentially reducing equipment downtime by 20-30%

- Proactive maintenance: Identifying significantly more potential issues before failure

- Process optimization: Contributing implementable improvement suggestions

- Knowledge transfer: Elevating team performance through peer mentoring

Organizations using advanced assessment methods report that selected operators complete preventive maintenance tasks 30-35% faster while identifying 50-60% more potential issues than those hired through traditional methods.

Implementation Requirements and Considerations

Realizing these projected returns would require more than simply deploying assessments. The organization would need to establish systematic performance measurement infrastructure to quantify improvement and validate ROI. Critical metrics to track would include:

- Individual productivity scores (units produced, tasks completed, uptime maintained)

- Safety performance indicators (near-misses reported, days without incidents)

- Quality metrics (error rates, rework frequency)

- Team contribution measures (peer ratings, knowledge sharing)

Without establishing baseline performance data, organizations cannot calculate the true value of improved selection. This measurement gap represents the primary barrier to ROI optimization in many manufacturing operations.

The Multiplication Effect Potential

Perhaps most significantly, research indicates that benefits of precision talent assessment compound over time. Higher-performing workers selected through advanced assessment methods typically demonstrate:

- Superior skill retention requiring less frequent retraining

- Greater adaptability to new equipment and procedures

- Enhanced ability to handle emergency situations

- Stronger safety culture propagation to new hires

These multiplier effects suggest that initial ROI calculations may underestimate long-term value creation by 30-50%.

For this manufacturing organization, implementing precision talent assessment for frontline roles where cognitive complexity meets physical danger could generate demonstrable economic returns of $800,000 to $1.5 million annually for 200 hires through job performance enhancement alone. When combined with projected safety improvements, reduced turnover, and decreased training costs, total ROI could approach or exceed seven figures.

The math is straightforward once organizations establish proper measurement variables. In an industry where performance differences – one of the direct inputs into the ROI analysis – can mean the difference between smooth operations and catastrophic failure, the case for investing in advanced talent assessment becomes compelling.